Services

Manufacturing Consulting

Whether your factory is new or has been running for decades, there are always areas where managers, operators and other staff can do better. Our consultants use decades of industry expertise to improve your quality, reduce lead times, assist in new factory set-up, and more—with the goal of introducing sustainable best practices and maintaining them over time.

Product Design

We created our company to improve the work-life balance. We believe that we need to focus on our family more than our work and finances.

Manufacturing Assessments And Observations

We offers the following helpful manufacturing assessments and observations: Initial assessment, factory walkthrough, and manufacturing process audits. Our consultants will deeply and holistically look into your factory's unique situation and suggest positive, lasting improvements.

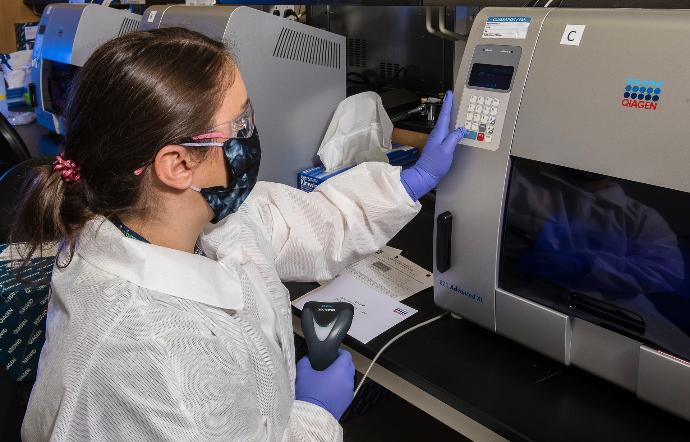

Product Testing and Certification

Testing and Certification Process Ensures Products Meet Standards and Perform as Intended . Before electrical, gas-powered or building products can be sold, installed or put into use, they must go through an extensive testing process to ensure they meet safety and code requirements.

Supporting organizations to comply, innovate and collaborate

Strategic Manufacturing Management

Manufacturing Management is a necessary part of optimizing your factory’s production and ultimately, improving your profitability. Our experts assist you in identifying high-value opportunities for improvement, and implementing deep, lasting changes in a facility and/or its office.

We can offer our expertise in:

-

“Increase first-time pass yield for 1 product

-

“Reduce New Product Introduction time ”

-

“Reduce the cost of a particular product line ”

-

“Set-up new facility and ensure full preparation before launch”

Electronics & Hardware Design

We provide design solutions for custom electronics & existing reference designs products and applications in Telemetry, IoT, Industrial IoT and Motor ECU, for medium to large scale field deployments. We support companies in teardown analysis of the product or boards or sub-assemblies and discovery & feasibility report for productization.

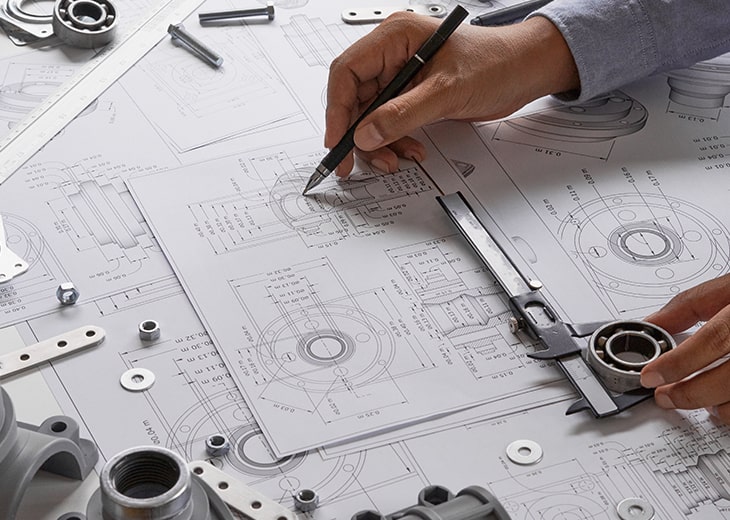

Industrial Design

Industrial Design

We follow below steps to convert your concept into a product:

Research - We do research on your concept and take your invention from the idea/ requirements you share.

Sketches - Various aspects of a product are looked into such as technology, styling, usability and the user experience.

3D design - We make a 3D design of enclosure of your product and visualize renders, shapes, size, assembly & fitments and ports.

Prototype - 3D prints are made for checking ergonomic and aesthetic design of the product.

Embedded Software Programming

We Creates Bespoke computer software, typically specialized for particular hardware written to control your specific machines or devices, that it runs on it

We undertake design, develop, test and deployment of firmware in embedded electronics.

-

Firmware architecture, design & development.

-

Porting and tuning existing firmware on alternate platform.

-

IoT IDE and OS stack management.

-

Process flow, Data modeling.

-

Sensor integration.

-

Edge security and API development & integration.

-

F/OTA enablement

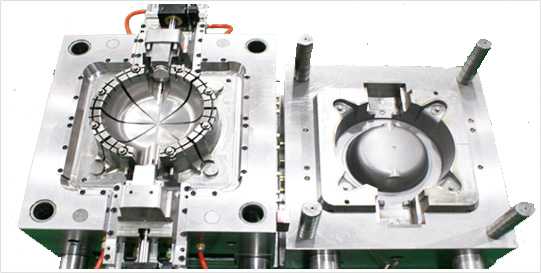

Molds and Tooling

Molds and Tooling

The main goal of mold design and tooling is to create a product with high manufacturability—a high-quality process that is simple and efficient, long-lasting, easy to operate and maintain, and that meets all customer specifications at the lowest possible cost.

Testing and Certification Process Ensures Products Meet Standards and Perform as Intended.

Before electrical, gas-powered or building products can be sold, installed or put into use, they must go through an extensive testing process to ensure they meet safety and code requirements.

Once a product successfully passes the testing process, it gains certification letting you know it is up to standard. It is also subject to follow-up inspections to ensure changes to the manufacturing process do not impact the product’s compliance.

A wide range of products require safety testing, including those manufactured in industries such as: Building products Cable/wiring Home appliances and electronics HVACR Industrial equipment IT equipment Life safety and security Lighting Medical equipment Personal protective equipment…..And much more!

There are thousands of national and international safety standards a product could be tested against. When you see a certification mark from a Nationally Recognized Testing Lab (NRTL), you can be confident that the product meets safety requirements, will function as intended and ultimately, help save property and lives.

Our References

We are in good company.